|

Note: If you are not at all familiar with basic electronics, you might find it easier to understand this chapter if you read chapter 12 first.

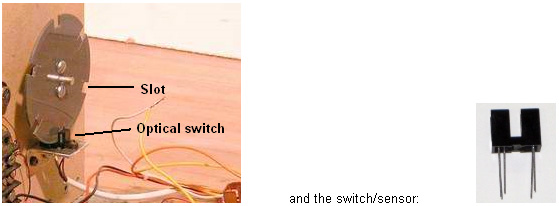

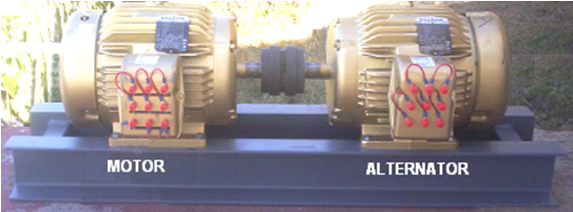

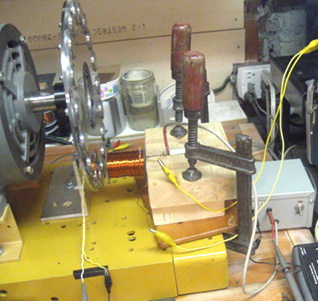

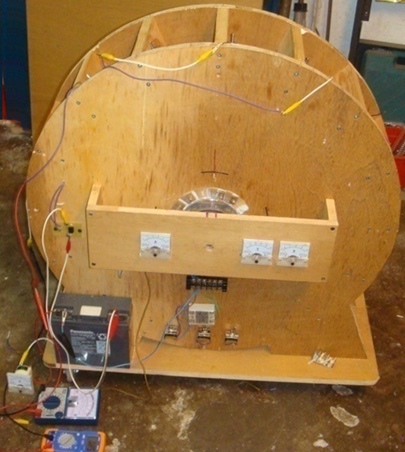

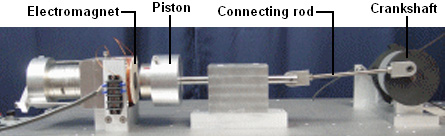

There are three categories of pulsed system and we will consider each in turn. These are drive-pulsed systems, energy-tapping pulsed systems and gravity free-energy pulsing systems. Here we will look at systems where an electrical pulse is used to cause the device to operate by creating a temporary magnetic field caused by electric current flowing through a coil or “electromagnet” as it is often called. Many of these systems are rather subtle in the way that they operate. One very well-known example of this is The Adams Motor. The late Robert Adams, an electrical engineer of New Zealand designed and built an electric motor using permanent magnets on the rotor and pulsed electromagnets on the frame of the motor. He found that the output from his motor exceeded the input power by a large margin (800%).  The diagram of his motor intended to show the basic operating principle is shown here:  If a motor is built like this, then it will most certainly work but it will never reach 100% efficiency let alone exceeding the 100% mark. It is only with a specific configuration which is hardly ever publicised that high performance figures can be achieved. While Robert has shown several different configurations, in order to avoid confusion I will describe and explain just one of them. I am indebted to several of Robert's friends and colleagues for the following information and I should like to express my thanks to them for their help and support in bringing you this information. First and foremost, high performance can only be achieved with the clever use of power collection coils. These coils need to be positioned accurately and their power collection restricted to just a very short arc of operation by connecting them to, and disconnecting them from, the output circuit at just the right instant so that the back EMF generated when the current draw stops, actually contributes to the drive of the rotor, speeding it on it's way and raising the overall efficiency of the motor/generator as a whole. Next, the shape of the magnets used is important as the length to width proportion of the magnet alters the pattern of it's magnetic fields. In direct opposition to the diagram shown above, the magnets need to be much longer than their width (or in the case of cylindrical magnets, much longer than their diameter). Further, a good deal of experimentation has shown that the size and shape of the electromagnets and pick-up coils has a major influence on the performance. The cross-sectional area of the core of the pick-up coils should be four times that of the cross-sectional area of the permanent magnets in the rotor. The reverse is true for the cores of the drive coils as their cores should have a cross-sectional area of just one quarter of the rotor magnet cross-sectional area. Another point which is almost never mentioned is the fact that big circuit gains will not be achieved unless the drive voltage is high. The minimum should be 48 volts but the higher the voltage, the greater the energy gain, so voltages in the 120 volts (rectified US mains voltage) to 230 volts (rectified mains voltage elsewhere) should be considered. Neodymium magnets are not recommended for drive voltages under 120 volts. This is one of Robert's test circuits:  Notice that the cores of the "generator" pick-up coils are very much wider than the cores of the drive coils. Also notice the proportions of the magnets where the length is much greater than the width or diameter. The four generator windings are mounted on a single disc allowing them to be moved through an angle to find the optimum operating position before being locked in position and the two drive coils are mounted separately and held clear of the disc. Notice also that the power pick-up coils are much wider compared to their length than the drive coils are. This is a practical feature which is explained in greater detail later. The DC input is shown passing through Robert's custom-made contactor switch which is mounted directly on the shaft of the motor/generator. This is a mechanical switch which allows an adjustable On / Off ratio, which is known as the "Mark/Space Ratio" or, if the "On" period is of particular interest, the "Duty Cycle". Robert Adams indicates that when the motor is running and has been adjusted to it's optimum performance, then the Mark/Space ratio should be adjusted to minimise the On period and ideally get it down to about 25% so that for three quarters of the time, the input power is actually switched off. There are various ways of achieving this switching while still having a very sharp turn on and turn off of the power. Robert considered mechanical switching of the drive current to be a very good option although he was not opposed to using the contact to power a transistor to do the actual switching and so reduce the current through the mechanical contacts by a major factor. His reasons for his preference for mechanical switching are that it gives very sharp switching, needs no electrical power to make it operate and it allows current to flow in both directions. The current flow in two directions is important because Robert produced various ways of getting the motor to feed current back into the driving battery, allowing it to drive the motor for long periods without lowering its voltage hardly at all. His preferred method of switching is shown here:   This switching gear operates as follows: The timing disk is bolted securely to the drive shaft of the motor and its position is set so that the electrical switch-on occurs when the rotor magnet is exactly aligned with the drive coil core. Adjustment of that timing is done by loosening the locking nut, rotating the disc very slightly and clamping the disc in position again. A spring washer is used to keep the assembly tight when the device is running. The disc has a star-shaped piece of copper sheet set into its surface and two silver-tipped, copper arm "brushes" slide across the surface of the copper star. One of these two brushes is fixed in position and slides across the copper star near the drive shaft, making a permanent electrical connection to it. The second brush slides alternatively on the non-conducting surface of the disc and then over the conducting arm of the copper. The second brush is mounted so that its position can be adjusted and, because the copper arms taper, that alters the ratio of the "On" time to the "Off" time. The actual switching is achieved by current flowing through the first brush, through the copper arm and then through the second brush. The brush arms shown in the diagram above rely on the springiness of the copper arm to make a good brush-to-copper electrical connection. It might be preferred to use a rigid brush arm, pivot it and use a spring to ensure a very good contact between the brush and the copper star at all times. The adjustment of the On to Off time, or "Mark/Space Ratio" or "Duty Cycle" as the technical people describe it, could perhaps do with some description. If the moveable brush is positioned near the centre of the disc, then, because of the tapering of the copper arms, the part of the non-conducting disc that it slides over is shorter and the part of the conducting copper arm with which it connects is longer, as the two sliding paths are about the same length, the current is on for about the same length as it is off, giving a Mark/Space ratio of about 50% as shown here:  If, instead, the moveable brush is positioned near the outside edge of the disc, then because of the tapering of the copper arm, the On path is shorter and the non-conducting Off path is very much longer, being about three times as long as the On path, giving a Mark/Space ratio of about 25%. As the moveable brush can be positioned anywhere between these two extremes, the Mark/Space ratio can be set to any value from 25% to 50%.  The two brushes can be on the same side of the drive shaft or on opposite sides as shown. One important feature is that the brushes touch in a position where the disc surface is always moving directly away from the brush mounting, causing any drag to be directly along the arm and giving no sideways loading on the brush. The diameter of the device is usually one inch (25 mm) or less. You will also notice that the output is switched although the diagram does not give any indication of how or when that switching takes place. You will notice that the diagram has angles marked on it for the optimum positioning of the pick-up coils, well, an Adams Motor builder with a forum ID of "Maimariati" who achieved a Coefficient Of Performance of 1,223, found that the optimum switching for his motor is On at 42 degrees and Off at 44.7 degrees. That tiny 2.7 degree part of the rotor turn gives a substantial power output and cutting the output current off at that point causes the back EMF of the coils to give the rotor a substantial additional boost on its way. His input power is 27.6 watts and his output power is 33.78 kilowatts Now for some practical details. It is suggested that a good length for the power pick-up coils can be determined by using the “paper clip test”. This is done by taking one of the permanent magnets used in the rotor, and measuring the distance at which that magnet just begins to lift one end of a 32 mm (1.25 inch) paper clip off the table. The optimum length of each coil from end to end is exactly the same as the distance at which the paper clip starts to lift.  The core material used in the electromagnets can be of various different types including advanced materials and alloys such as ‘Somalloy’ or 'Metglas'. The power pick-up coil proportions are important as an electromagnet becomes less and less effective as its length increases, and eventually, the part furthest from the active end can actually be a hindrance to the effective operation. A good coil shape is one which you would not expect, with the coil width being, perhaps 50% greater than the coil length: Contrary to what you would expect, the device draws in energy from the local environment better if the end of the pick-up coil farthest from the rotor is left unaffected by any other part of the device and the same applies to the magnet facing it. That is, the coil should have the rotor at one end and nothing at the other end, that is, no second rotor behind the coil. The speed at which the voltage is applied to, and removed from, the coils is very important. With very sharp voltage rises and falls, additional energy is drawn from the surrounding environmental energy field. If using transistor switching, then the IRF3205 FET has been found to be very good and a suitable driver for the FET is the MC34151. If using a Hall-effect semiconductor to synchronise the timing, say the UGN3503U which is very reliable, then the life of the Hall-effect device is much improved if it is provided with a 470 ohm resistor between it and the positive supply line, and a similar 470 ohm resistor between it and the negative line. These resistors in series with the Hall-effect device effectively “float” it and protect it from supply-line spikes".  Here, two electromagnets are driven by the battery via Robert's 4-arm commutator which is mounted on the rotor shaft. Some of the recommendations given by Robert are the opposite of what you would expect. For example, he says that a single rotor construction tends to be more electrically efficient that one where several rotors are mounted on a single shaft. Robert is against the use of reed switches and he recommends making one of his commutators. At one stage, Robert recommended the use of standard transformer shims for constructing the cores of the electromagnets. This has the advantage that matching bobbins for holding the coil windings are readily available and can still be used for pick-up coils. Later on, Robert swung towards the use of solid cores from the old PO Series 3000 telephone relays and eventually said that electromagnet cores should be solid iron.  The diagrams presented by Robert show the magnets located on the rim of the rotor and pointing outwards. If this is done, then it is essential that the magnets in the rotor are firmly attached on at least five of their six faces and the possibility of using a ring of non magnetic material such as duct tape around the outside should be considered. That style of construction also lends itself to streamlining the rotor by having a completely solid construction, although it might be remarked that the motor would run better and more quietly if it were enclosed in a box which had the air pumped out of it. If that is done, then there will be no air resistance and because sound can't pass through a vacuum, quieter operation is bound to result. While this may sound a bit complicated, there is no reason why it should be. All that is needed is two discs and one central disc which is the thickness of the magnets, with slots cut in it, the exact size of the magnets. The assembly starts with the lower disc, magnets and central disc. These are glued together, probably with epoxy resin, and that holds the magnets securely on four faces as shown here:  Here, the magnets are attached on the lower face, the right and left faces, and the unused pole face, and when the upper disc is attached, the upper faces are also secured and there is the minimum of air turbulence when the rotor spins:  There is a "sweet spot" for the positioning of the power pick-up coils and it will usually be found that this is two or three millimeters away from the rotor. If that is the case, then there will be room for an outer band of duct tape on the rim of the rotor to provide additional protection against the failure of the magnet attachment method. High-power versions of the motor/generator need to be enclosed in a metal box which is earthed as they are quite capable of generating a substantial amount of high frequency waves which can damage equipment such as oscilloscopes and create TV reception interference. There would probably be an improvement in performance as well as a reduction in sound if the box was airtight and had the air pumped out of it. If that is done, then there will be no air resistance as the rotor spins and since sound does not pass through a vacuum, quieter operation is possible. Experienced rotor builders do not like the radial magnets style of construction because of the stresses on the magnet attachments if high rotational speeds are reached. It should not need to be said, but it is obviously a major requirement to keep your hands well away from the rotor when the motor is running as it is perfectly possible to be injured by the high-speed movement if you are careless. Please remember that this presentation must not be considered to be a recommendation that you build or use any device of this nature and it must be stressed that this text, in common with the entire contents of this eBook, is intended to be for information purposes only and no representations or warranties are implied by this presentation. Should you decide to construct, test or use any device, then you do so entirely at your own risk and no liability attaches to anybody else if you sustain any kind of injury or property damage as a result of your own actions. Because of the mechanical stresses caused during rotation, some experienced constructors feel that the magnets should be embedded in the rotor as shown here where they are kept well clear of the rim of a rotor which is made from a tough material. This is so that the outer strip of the material prevents the magnets breaking loose and becoming dangerous high-speed projectiles, which at best would destroy the electromagnets and at worst could injure someone quite badly:  It needs to be remembered that the proportions of the magnets are for the magnet length to be more than the diameter, so in cases like this where circular magnet faces are to be used, the magnets will be cylindrical and the rotor needs to have a significant thickness, which will depend on the magnets which are available locally. The magnets should be a tight push-fit in their holes and securely glued in place. Robert Adams has used this construction style as well. However, if an arrangement like this is used, then there will be a substantial sideways pull on the rotor as it reaches the electromagnet core, tending to pull the magnets out of the rotor.  It is important that the rotor should be perfectly balanced and have the minimum amount of bearing friction possible. This calls for precision construction and either roller or ball bearings. The construction style shown above has the distinct advantage that it has an open end to both the magnet and the coils and this is believed to facilitate the inflow of environmental energy into the device. It may be my ignorance showing here, but I have a problem with this version. The difficulty as I see it is that the magnet/core pull and the subsequent drive thrust when the coil is powered, form a "turning couple" as they both try to rotate the axle in the same direction. This places a substantial loading on the axle bearings, usually amplified by the radius of the rotor being greater than the distance from the rotor to the axle bearings. This load will be in the tens of kilograms range and will be applied and reversed perhaps forty times per second. To me, that appears like a vibration load and is directly opposed to the "perfectly balanced" rotor operation being sought. The radial magnet arrangement generally shown by Robert Adams does not have any of this kind of loading at all because the coils are exactly opposite each other and their loads cancel each other out exactly. The choice is, of course, up to the builder and his assessment of the advantages and disadvantages of the different styles of construction. When getting ball-race bearings for an application like this, please be aware that "closed" bearings such as these are not suitable as supplied:  This is because this type of bearing is usually packed with dense grease which completely destroys its free motion, making it worse as a bearing than a simple hole-and-shaft arrangement. However, in spite of this, the closed or "sealed" bearing is popular as the magnets tend to attract dirt and dust and if the device is not enclosed in a steel box as is necessary for the high power versions, then having the seal is considered to be an advantage. The way to deal with the grease packing is to soak the bearing in an isopropyal solvent cleaner to remove the manufacturer's grease, and then, when it has dried out, lubricate the bearing with two drops of a high quality thin oil. If it is intended to house the motor/generator in an earthed, sealed steel box then an alternative type of bearing which might be suitable is an open design like this:  especially if the air is removed from the box. Some constructors perfer to use ceramic bearings which are supposed to be immune to dirt. One supplier is here but as with everything else, these choices have to be made by the builder and will be influenced by his opinions. I'm not sure where it came from, but here is a circuit diagram showing a transistor drive and the return of the back EMF of the drive coils to the driving power supply. Using this method, about 95% of the drive current can be returned, lowering the current draw enormously:  The diode feeding the power back to the supply is a Schottky type because of it's high-speed operation. It needs to be able to handle the peak pulse power and so should be one of the more robust types. What this circuit does not have is the very important switching on the output coils circuit. Another strange item is the way that the FET sensor is arranged with two sensors rather than one and with an additional battery. While it must be admitted that the current draw of the FET gate should be very low, there still does not seem to be much reason to have a second power supply. One other peculiarity in this diagram is the positioning of the drive coils. With them offset as shown, it has the effect of them being at an angle relative to the rotor magnets. It is not at all clear if this is an advanced operating technique or just poor drawing - I am inclined to assume the latter although I have no evidence for this other than the circuit design and the low quality of the original drawing which had to be improved considerably to arrive at the diagram shown above. The coil generator output should be fed into a capacitor before being passed to whatever equipment is to be powered by the device. This is because the energy is being drawn from the local environment and is not conventional energy. Storing it in a capacitor converts it to a more normal version of electrical power, a feature which has also been mentioned by Don Smith and by John Bedini although their devices are quite different in operation. The DC resistance of the coil windings is an important factor. The overall resistance should be either 36 ohms or 72 ohms for a complete set of coils, whether they are drive coils or power pick-up coils. Coils can be wired in parallel or in series or in series/parallel. So, for 72 ohms with four coils, the DC resistance of each coil could be 18 ohms for series-connected, 288 ohms for parallel connected, or 72 ohms for connection in series/parallel where two pairs of coils in series are then wired in parallel. To help with assessing the wire diameter and length which you could use, here is a table of some of the common sizes in both American Wire Gage and Standard Wire Gauge:  So far, we have not discussed the generation of the timing pulses. A popular choice for a timing system is to use a slotted disc mounted on the rotor axle and sensing the slots with an "optical" switch. The "optical" part of the switch is usually performed by UV transmission and reception and as ultra violet is not visible to the human eye, describing the switching mechanism as "optical" is not really correct. The actual sensing mechanism is very simple as commercial devices are readily available for performing the task. The sensor housing contains both a UV LED to create the transmission beam, and a UV dependent resistor to detect that transmitted beam. Here is an example of a neatly constructed timing mechanism made by Ron Pugh for his six-magnet rotor assembly:  This device happens to be one which is supplied here under their product code number : OP-5490-14327-00. As the slotted disc rotates, one of the slots comes opposite the sensor and allows the UV beam to pass through to the sensor. That lowers the resistance of the sensor device and that change is then used to trigger the drive pulse for whatever length of time the slot leaves the sensor clear. You will notice the balanced attachment method used by Ron to avoid having an unbalanced rotor assembly. There can be two timing discs, one for the drive pulses and one for switching the power pickup coils in and out of the circuit. The slots in the power pick-up timing disk will be very narrow as the switch-on period is only about 2.7 degrees. For a six-inch diameter disc where 360 degrees represents a circumference length of 18.85 inches (478.78 mm) a 2.7 degree slot would be only 9/64 inch (3.6 mm) wide. The arrangement for an axial magnet rotor set-up could be like this:  So to recap, the things which are necessary for getting an Adams Motor output into the serious bracket are:

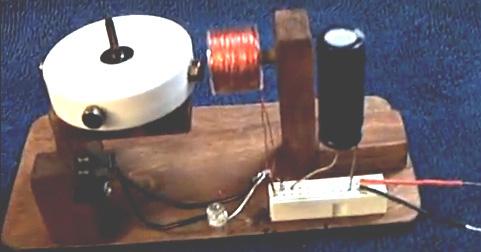

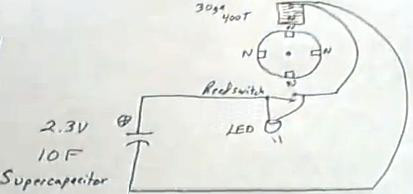

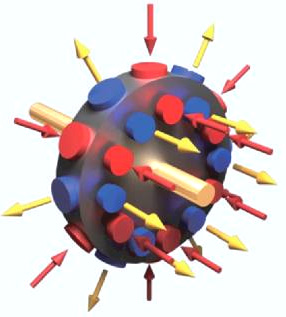

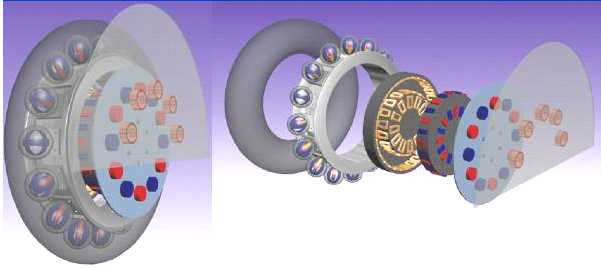

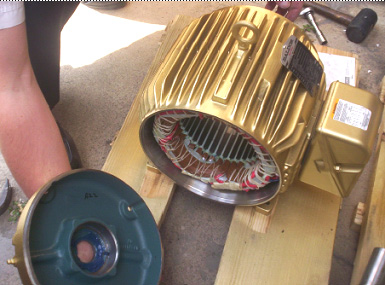

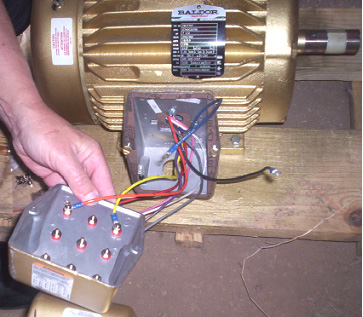

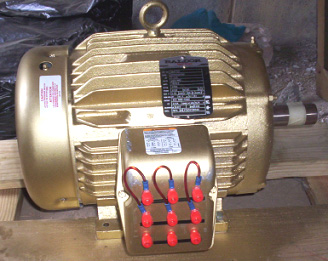

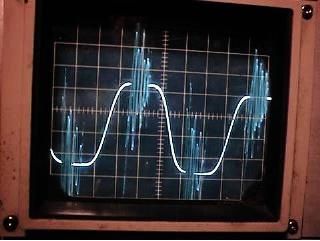

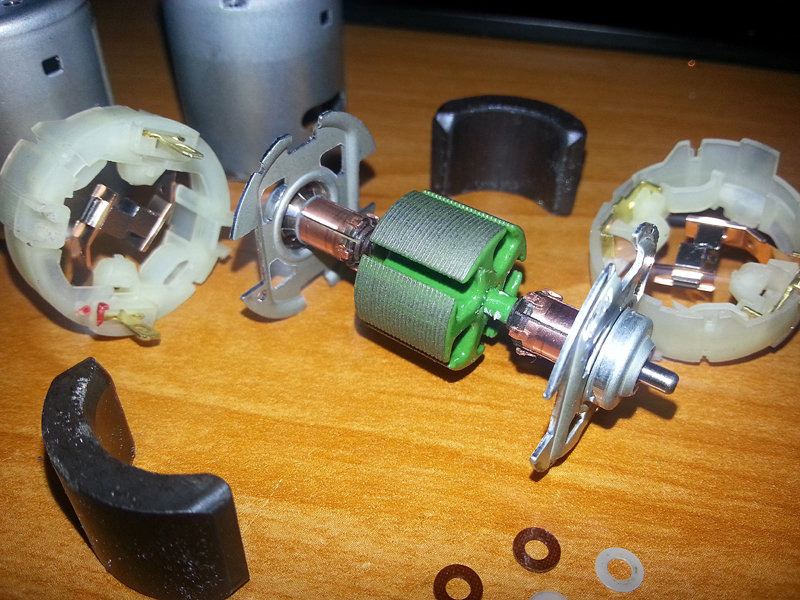

If you want the original drawings and some explanation on the operation of the motor, then two publications from the late Robert Adams can be bought from www.nexusmagazine.com where the prices are quoted in Australian dollars, making the books look much more expensive than they actually are. Here is a really impressive collection of well-informed practical material on building and using an Adams motor with details of sensors and how they work, core materials and their performances and how to locate the "sweet spot" - very highly recommended web site. Lidmotor’s Low-voltage Rotor One very experienced developer whose YouTube ID is “Lidmotor” (because he makes motors from the lids of jars) has a short video here showing a very simple rotor design with one of his jar lids mounted on a single bearing:  The white lid has four magnets attached to it spaced out evenly around the lid at ninety-degree intervals. Facing them is an air-core coil mounted on a non-magnetic support dowel and wound with 400 turns of ’30-gauge’ wire on a plastic spool. As ‘Lidmotor’ is American, the ’30 gauge’ wire is likely to be American Wire Gauge #30 with a diameter of 0.255 mm as opposed to the European Standard Wire Gauge size which has a 0.315 mm diameter. An air-core coil has no effect on the passing rotor magnets IF it is not carrying current. An output coil will cause drag on the rotor if current is being drawn from the coil, and so timed output switching as used by Robert Adams would be needed to not just overcome the drag, but to push the rotor on its way as well. There are two very important features of this rotor drive design. One is the fact that a supercap (10-Farad, 2.3V) is used to drive the rotor and when supplied with a charge of only 0.5V to 1.0V, can spin the rotor for up to thirty minutes. That very long time is likely to be a feature of the second important item which is that he has placed an LED across the reed switch used to power the coil. When the reed switch opens, a back-EMF voltage spike occurs and the LED feeds that voltage pulse back into the 100% efficient supercap, recovering most of the current used to drive the rotor. This is the same method as used by Robert Adams in his motor designs. Lidmotor presents his circuit like this:  While the circuit shows the magnet operating the reed switch as being 180 degrees around from the coil, the photograph indicates that the switching magnet is one 90 degrees away. Any of the other magnets can be used. The reed switch operation is adjusted to get the best performance. This is done by moving the switch backwards and forwards along the moving path of the magnet to make the switching occur earlier or later. The objective is to push the rotor magnet on its way by pulsing the coil very briefly just after the rotor magnet has passed the centre of the coil. The length of time that the reed switch is closed can be adjusted by moving the switch closer to the magnet for a longer switch-closed time, or further away for a shorter switch closure. It is also possible to alter the closed time by positioning the switch across the path of the magnet travel or parallel to it. If you are not familiar with a reed switch, it is just a glass tube, filled with an inert gas, and with two overlapping metal strips inside the tube:  The external magnetic field magnetises the strips and they spring together due to magnetic attraction and spring apart again when the magnetic field moves away. These switches come in various sizes and the smallest version tends to be unreliable and has a very low maximum current capacity. The larger versions are much more robust. Lidmotor’s circuit is very simple and very effective, even though the rotor will have minimal weight and no significant drag. One wonders if adding a second coil and a diode feeding the supercapacitor, if the system could not become self-running. Phemax's Inertial-Propulsion and Electrical-Generation System. Phemax Technologies, Inc. have developed what they describe as their 'sustainable transportation system' which is based on their inertial-propulsion generation wheel, which uses what they call '3-D Coraxial Hybrid Induction' (CHI), in which 'Coraxial' refers to their "combined radial-axial" technique where drive is provided by a radial pulsed magnet system and power extraction is achieved using an axially-orientated magnet/coil system.  Taiwan inventor, Tajen (David) Chi, says that his company, "Phemax Technologies Inc." will be demonstrating their technology in September 2010 at an expo, after which they will allow interested and qualified parties to come to their premises for licensing discussions. Their device can take the place of the battery component of an electric vehicle or it can be used to supplement and recharge a battery bank in the vehicle. At the September exhibition, they will allow visitors to ride their 2 kW test car. David intends to put their test data on the Internet. With a rotational input of 1 NM at 500 rpm, a single inertial-propulsion generation wheel can produce 1 KW of axial generative power. David also said that a 150W output from his motor actually produces between 180 and 200 watts of mechanical output, while a 1500W output produces a mechanical output of 1800 to 2000 watts (96 Volts at 20 Amps), as measured by a watt meter, speed meter, torque meter, and oscilloscopes. He says that these measurements were made by Michael Hseuh, Vice President and Chief Technology Officer. Ceramic-based and carbon-based ultra-capacitors are used to return some of the output power to the input in order to keep the machine running continuously without the need for a power supply when the engine is running and providing it's output. When driving a vehicle powered by this device, the mechanical driving torque is provided via a continuously-variable transmission. At this time, Phemax Technologies, Inc. have a 150-Watt and a 2 kW prototype which they plan to demonstrate in September 2010. He says that they generally run these prototypes for eight hours each day in their lab. The central principle of the Phemax Technologies Inc. process is what they call "CORAXIA" which stands for "combined radial-axial" hybrid induction, abbreviated to "CHI", which is David's surname. They also call this the "3-D Coaxial Hybrid Induction" system. They state that their electromagnetic 3-D arrangement enables the wheel to have both radial flux propulsion and axial flux generation with just a single rotor and two separate stators. As the radial electric drive rotates, the mechanical energy due to the inertia of the wheel and the ground power transmission mechanism enables the wheels of a vehicle to generate electricity as they rotate. There are two videos showing the device generating electricity: here and here Another application is where the electrical output from the device is being used to produce a hydrogen/oxygen gas mix from water using an underwater plasma arc. David says he is self-taught in this area. He has three patents: Taiwan patent M352472, M372891 and M382655 (which are not in English). From his search of the patent index, the Internet and YouTube, David said he has not yet seen a patent or experimental set-up similar to what they have developed. This motor/generator is unusual in that it uses pulsed rotor drive on magnets mounted on the circumference of the rotor and simultaneously, it picks up electrical energy from a coil/magnet arrangement mounted on the side faces of the rotor as shown here:    The basic drive/generator unit can be replicated on a single shaft to give increased power, still without increased frictional losses between the drive and the power generation:  It is unusual to see this technique used as it can be difficult to avoid interaction between the different magnetic fields. However, David has been entirely successful in doing this and the arrangement has no transmission losses between the drive motor and the generator as these are integral components of the system. This system is capable of driving a self-powered air-conditioning unit and a 5 kW proof-of-concept prototype is shown here:  This device is also capable of driving electric lighting and with a 5 kilowatt output self-powered output, it can power most household needs. A typical washing machine has a 2.25 kilowatt maximum electrical draw as does the average tumble-dryer. Most fan-heaters are 3 kilowatts or less when on full output. If a wind-power generator is already in place, then using the mechanical power of the generator to spin the axle of one of these CHI generators results in a very high-power electricity generation system. Contact: Tajen (David) Chi, Taiwan e-mail: chitajen@gmail.com Inquiries to: Phemax Technologies Inc., Michelle Chen, Manager of Marketing and Business Development. Tel: 886-2-2371-5622 e-mail: michelle@phemax.com The exhibition is at: The 6th Taipei International Invention Show & Technomart, website running from 30th September 2010 to 3rd October 2010 at the Taipei World Trade Centre, Exhibition Hall 1. Raymond Kromrey. Where the objective is to produce electricity from a rotating magnetic field, there has always been a search for some method of either reducing, or eliminating altogether, the drag on the rotor when electric current is drawn from the generator. One design which claims to have very limited drag caused by current draw is the Kromrey design. The main characteristics of this design are said to be: 1. It has almost constant electrical power output even when the rotor speed is altered by as much as 35%. 2. It can continue to operate with it's electrical output short-circuited, without heating the rotor or causing a braking effect. 3. The production efficiency (electrical output divided by the driving force) is high. 4. The frequency of it's AC output power can be adjusted to that required by the equipment which it powers. 5. The rotor can be spun at any rate from 800 rpm to 1,600 rpm. 6. The simple construction allows manufacturing costs to be about 30% less than other generators. 7. This generator is recommended for supplying power at or above the 1 kilowatt level. Here is the patent for this device: Patent US 3,374,376 19th March 1968 Inventor: Raymond KromreyELECTRIC GENERATOR My present invention relates to an electric generator which converts magnetic energy into electric energy using two components which can rotate relative to each other, i.e. a stator and a rotor, one having electromagnets or permanent magnets which induce a voltage in a winding which forms part of an output circuit mounted on the other component. Conventional generators of this type use a winding which whose conductors form loops in different axial planes so that opposite parts of each loop pass through the field of each pole pair, twice per revolution. If the loops are open circuit, then no current flows in the winding and no reaction torque is developed, leaving the rotor free to turn at the maximum speed of its driving unit. As soon as the output winding is connected across a load or is short-circuited, the resulting current flow tends to retard the motion of the rotor to an extent which depends on the intensity of the current and this makes it necessary to include compensating speed-regulating devices if it is necessary to maintain a reasonably constant output voltage. Also, the variable reaction torque subjects the rotor and its transmission to considerable mechanical stresses and possible damage. It is therefore the general object of this invention to provide an electric generator which has none of the above disadvantages. Another object is to provide a generator whose rotor speed varies very little in speed between open circuit operation and current delivery operation. Another objective is to provide a generator whose output voltage is not greatly affected by fluctuations in its rotor speed. I have found that these objectives can be achieved by rotating an elongated ferromagnetic element, such as a bar-shaped soft-iron armature, and a pair of pole pieces which create an air gap containing a magnetic field. Each of the outer extremities of the armature carries a winding, ideally, these windings are connected in series, and these coils form part of a power output circuit used to drive a load. As the armature rotates relative to the air gap, the magnetic circuit is intermittently completed and the armature experiences periodic remagnetisations with successive reversals of polarity. When the output circuit is open, the mechanical energy applied to the rotor (less a small amount needed to overcome the friction of the rotating shaft) is absorbed by the work of magnetisation, which in turn, is dissipated as heat. In actual practice however, the resulting rise in temperature of the armature is hardly noticeable, particularly if the armature is part of the continuously air-cooled rotor assembly. When the output circuit is closed, part of this work is converted into electrical energy as the current flow through the winding opposes the magnetising action of the field and increases the apparent magnetic reluctance of the armature, and so the speed of the generator remains substantially unchanged if the output circuit is open or closed. As the armature approaches its position of alignment with the gap, the constant magnetic field tends to accelerate the rotation of the armature, aiding the applied driving force. After the armature passes through the gap there is a retarding effect. When the rotor picks up speed, the flywheel effect of its mass overcomes these fluctuations in the applied torque and a smooth rotation is experienced. In a practical embodiment of this invention, the magnetic flux path includes two axially spaced magnetic fields traversing the rotor axis and substantially at right angles to it. These fields are generated by respective pole pairs co-operating with two axially spaced armatures of the type already described. It is convenient to arrange these two armatures so that they lie in a common axial plane and similarly, the two field-producing pole pairs also lie in a single plane. The armatures should be laminated to minimise eddy currents, so they are made of highly permeable (typically, soft-iron) foils whose principle dimension is perpendicular to the rotor axis. The foils can be held together by rivets or any other suitable method. If the ferromagnetic elements are part of the rotor, then the output circuit will include the usual current-collecting means, such as slip-rings or commutator segments, depending on whether AC or DC current output is desired. The source of coercive force in the stator includes, advantageously, a pair of oppositely positioned, yoke-shaped magnets of the permanent or electrically energised type, whose extremities constitute the pole pieces mentioned above. If electromagnets are used in the magnetic circuit, then they may be energised by an external source or by direct current from the output circuit of the generator itself. I have found that the terminal voltage of the output circuit does not vary proportionately to the rotor speed as might be expected, but instead, it drops at a considerably slower rate with decreasing rotor speed. So, in a particular tested unit, this voltage fell to only about half its original value when the rotor speed was dropped to one third. This non-linear relationship between terminal voltage and driving rate produces a substantially constant load current and therefore, electric output over a wide speed range, at least under certain load conditions, inasmuch as the inductive reactance of the winding is proportional to frequency (and consequently, to rotor speed) so as to drop off more rapidly than the terminal voltage, in the event of a speed reduction, with a resulting improvement in the power factor of the load circuit. If the magnetic circuit contains only a single pole pair per air gap, the flux induced in the rotating armature will change its direction twice per revolution so that each revolution produces one complete cycle of 360 electrical degrees. In general, the number of electrical degrees per revolution will equal 360 times the number of pole pairs, it being apparent that this number ought to be odd since with even numbers it would not be possible to have poles alternating in polarity along the path of the armature and at the same time to have the North and South poles of each pair at diametrically opposite locations. In any case, it is important to dimension the curved facing faces of the pole pairs in such a manner so as to avoid allowing the armature to bridge between adjoining poles, so it is necessary to make the sum of the arcs spanned by these faces (in the plane of rotation) equal to considerably less than 360 degrees electrical. The invention will now be described in more detail, reference being made to the accompanying drawings in which:  Fig.1 and Fig1A. illustrate a first embodiment of my invention, shown in axial section and in a cross-sectional view taken on line IA - IA of Fig.1 respectively.  Fig.2 and Fig.3 are perspective views illustrating two other embodiments.   Fig.4 and Fig.5 illustrate diagrammatically, two output circuit arrangements, one for a DC output and one for an AC output.  Fig.6 is a somewhat diagrammatic illustration of an arrangement for comparing the outputs of a conventional generator and a generator according to this invention.  The generator 100 shown in Fig.1 and Fig.1A comprises a stator 101 and a rotor 102 which has a pair of laminated armatures 102' and 102", carried on a shaft 103 which is free to rotate in bearings mounted in the end plates 104' and 104", of a generator housing 104 which is made from non-magnetic material (e.g. aluminium) which is rigidly attached to the stator.  Shaft 103 is coupled to a source of driving power indicated diagrammatically by an arrow 110. The stator 101 includes a pair of yoke-shaped laminated electromagnets 101' and 101" whose extremities form two pairs of co-planar pole pieces, designated respectively 101a, 101b (North magnetic pole) and 101c, 101d (South magnetic pole). The pole pieces have concave faces, facing towards the complimentary convex faces 102a, 102d of armature 102' and 102b, 102c of armature 102". These faces whose concavities are all centred on the axis of shaft 103, extend over arcs of approximately 20o to 25o each in the plane of rotation (Fig.1A) so that the sum of these arcs adds up to about 90o geometrically and electrically.  The stator magnets 101', 101" are surrounded by energising windings 109', 109" which are connected across a suitable source of constant direct current (not shown). Similar windings, each composed of two series-connected coils 106a, 106d and 106b, 106c, surround the rotor armatures 102' and 102", respectively. These coils form part of an output circuit which further includes a pair of brushes 107', 107" which are carried by arms 108', 108" on housing 104 with mutual insulation brushes 107', 107" co-operate with a pair of commuter segments 105', 105" (see also Fig.4) which are supported by a disc of insulating material 105, mounted on shaft 103.  By virtue of the series-connection of coils 106a-106d between the segments 105' and 105", as illustrated in Fig.4, the alternating voltage induced in these coils gives rise to a rectified output voltage at brushes 107' and 107". The unidirectional current delivered by these brushes to a load (not shown) may be smoothed by conventional means, represented by capacitor 112 in Fig.4.  Fig.2, shows a modified generator 200, whose housing 204, supports a stator 201 essentially consisting of two permanent bar magnets 201' and 201", extending parallel to the drive shaft 203 (on opposite side of it), each of these magnets being rigid and each having a pair of sole shoes 201a, 201c and 201b, 201d respectively. Rotor 202 is a pair of laminated armatures 202' and 202",similar to those of the previous embodiment, whose output coils 206a, 206b, 206c and 206d are serially connected between a slip-ring 205', supported on shaft 203 through the intermediary of an insulating disc 205, and another terminal here represented by the grounded shaft 203 itself. Slip-ring 205' is contacted by brush 207 on holder 208, the output of this brush being an alternating current of a frequency determined by the rotor speed.  Fig.3 shows a generator 300 which is basically similar to the generator 100 shown in Fig.1 and Fig.1A. It's shaft 303 carries a pair of laminated soft-iron armatures 302', 302" which can rotate in the air gaps of a pair of electromagnets 301', 301" which have windings 309' and 309". The commutator 305 again co-operates with a pair of brushes 307, only one of which is visible in Fig.3. This brush, carried on an arm 308, is electrically connected to a brush 313 which engages with a slip-ring 314 positioned on an extremity of shaft 303 which also carries two further slip-rings 315', 315" which are in conductive contact with ring 314 but are insulated from the shaft. Two further brushes 316', 316" contact the rings 315', 315" and respectively are connected to windings 309' and 309". The other ends of these windings are connected to an analogous system of brushes and slip-rings on the extremity of the opposite shaft, and arranged so that the two commutator brushes are effectively bridged across the windings 309' and 309" in parallel. Therefore, in this embodiment, the stator magnets are energised from the generator output itself, it being understood that the magnets 301' and 301" (made, for example, of steel rather than soft iron) will have a residual coercive force sufficient to induce an initial output voltage. Naturally, the circuits leading from the brushes 307 to the windings 309', 309" may include filtering as described in connection with Fig.4.  Fig.6 shows a test circuit designed to compare the outputs of a generator of this design, such as the unit 100 of Fig.1 and Fig.1A, with a conventional generator 400 of the type having a looped armature 402 which rotates in the gap of a stator magnet 401 which is fitted with energising windings 409', 409". The two generators are interconnected by a common shaft 103 which carries a flywheel 117. This shaft is coupled through a clutch 118 to a drive motor 111 which drives the rotors 402 and 102 of both generators in unison, as indicated by arrow 110. Two batteries 120 and 420, in series with switches 121 and 421, represent the method of supplying direct current to the stator windings 109', 109" and 409', 409" of the two generators. The rectified output of generator 100 is delivered to a load 122, shown here as three incandescent lamps connected in series, and with a combined consumption of 500 watts. Generator 400, provides current into an identical load 422. Two wattmeters 123 and 423 have their voltage and current windings connected respectively in shunt and in series with their associated loads 122 and 422, to measure the electric power delivered by each generator. When clutch 118 is engaged, shaft 113 with it's flywheel 117 is brought to an initial driving speed of 1,200 rpm. at which point, the switch 421 in the energising circuit of the conventional generator 400, is closed. The lamps 422 light immediately and the corresponding wattmeter 423 shows an initial output of 500 watts. However, this output drops immediately as the flywheel 117 is decelerated by the braking effect of the magnetic field on armature 402. Next, the procedure is repeated but with switch 421 open and switch 121 closed. This energises generator 100 and the lamps 122 light up, wattmeter 123 showing an output of 500 watts, which remains constant for an indefinite period of time , there being no appreciable deceleration of flywheel 117. When the clutch 118 is released and the rotor speed gradually decreases, the output of generator 100 is still substantially 500 watts at a speed of 900 rpm. and remains as high as 360 watts when the speed dropped further to 600 rpm. In a similar test with a generator of the permanent magnet type, such as the one shown at 200 in Fig.2, a substantially constant output was observed over a range of 1600 to 640 rpm. Teruo Kawai. In July 1995, a patent was granted to Teruo Kawai for an electric motor. In the patent, Teruo states that a measured electrical input 19.55 watts produced an output of 62.16 watts, and that is a COP of 3.18. The main sections of that patent are included on this site.   In this motor, a series of electromagnets are placed in a ring to form the active stator. The rotor shaft has two iron discs mounted on it. These discs have permanent magnets bolted to them and they have wide slots cut in them to alter their magnetic effect. The electromagnets are pulsed with the pulsing controlled via an optical disc arrangement mounted on the shaft. The result is a very efficient electric motor whose output has been measured as being in excess of its input. James Hardy’s Self-Powered Water-pump Generator. There is a video on Google which shows a self-powered electrical water-pump driven, electrical generator at this location. This is a very simple device where the jet of water from the pump is directed at a simple water-wheel which in turn, spins an electrical alternator, powering both the pump and an electric light bulb, demonstrating the capture and use of free-energy.   Initially, the generator is got up to speed, driven by the mains electrical supply. Then, when it is running normally, the mains connection is removed and the motor/generator sustains itself and is also able to power at least one light bulb. The generator output is normal mains current from a standard off-the-shelf alternator. James has Patent Application US 2007/0018461 A1 published in 2007 on his design. In that application he points out that a major advantage of his design is the low noise level produced when the generator is running. In the video and the pictures above, the demonstration has the housing opened up in order to show how the generator system works, but during normal use, the compartments are completely sealed. In his document, James shows the overall system like this:  The housing is divided into three separate compartments. The first compartment has a strong axle shaft running through it, supported on ball or roller bearings – possibly ceramic for this environment. The bearings are protected by being covered by splash guards which keep the water (or other liquid) off them. A waterwheel of almost any type is mounted on the shaft and a high-capacity water pump directs a stream of liquid on to the waterwheel, striking the paddles at right angles in order to provide the maximum impact. This first compartment is sealed in order to contain all of the liquid inside it and the bottom is effectively a sump for the liquid. A pipe located near the bottom of the compartment feeds the liquid to the pump which is located in the second compartment. The pump boosts the liquid through a nozzle, directing it at the waterwheel. While almost any nozzle will work, it is usual to choose one which produces a concentrated jet of liquid in order to generate the largest possible impact. One would expect that the larger the diameter of the waterwheel, the more powerful the system would be. However, that is not necessarily the case as other factors such as the overall weight of the rotating members might affect the performance. Experimentation should show the most effective combination for any given pump. The rotating shaft is given a third bearing supported by the side of the final compartment. The shaft then has a large diameter belt pulley mounted on it, the belt driving a much smaller pulley mounted on the shaft of the generator. This raises the rate at which the generator shaft is rotated. If the pump operates on AC mains voltage, then the generator will be one which generates mains voltage AC. If the pump operates on, say, 12 volts, then the generator will be one which generates 12 volts DC. The diagram above, shows the arrangement for a mains voltage system as that is probably the most convenient. If a 12-volt system is chosen, then the inverter can be omitted. The generator is started by pressing the ‘normally open’ press-button switch marked “A” in the diagram. This passes the battery power through to the 1-kilowatt inverter which then generates AC mains voltage. The switch marked “B” is a “changeover” switch, and for starting, it is set so that it passes the AC power through switch “A” to the pump. This causes the pump to turn on and direct a powerful jet of liquid at the waterwheel, forcing it around and so powering the generator. When the generator gets up to full speed, switch “B” is flipped over, disconnecting the inverter and feeding the generator power through to the pump, keeping it running and supplying additional power to the output power sockets mounted on top of the housing. The press-button switch is released, disconnecting the battery which is no longer needed. Switch “C” is an ordinary On/Off mains switch which is needed if you want to turn the generator off. A major advantage of this generator system is that the main components can be bought ready-made and so only very simple constructional skills and readily available materials are needed. Another advantage is that what is happening can be seen. If the pump is not working, then it is a simple task to discover why. If the generator is not spinning, then you can see that and sort the problem. Every component is simple and straightforward. James suggests that a suitable pump is the 10,000 gallons per hour “Torpedo Pump” from Cal Pump web site:  Georges Mourier’s COP=10,000 Motor/Generator Patent This patent from Frenchman Georges Mourier is quite remarkable in that it states clearly in the patent that it has a Coefficient Of Performance of 10,000 with an input power of just 10 watts producing an output of 100 kilowatts, which, considering the massive opposition of the US Patent Office to any claim of output power being greater than the input needed to produce that output, is little short of amazing. This patent contains a fair amount of mathematics where Georges goes about showing why there is a power amplification. This can be ignored by most people as the point to concentrate on is how to build a power-amplifying motor/generator. Electrical machine operating as a generator or as an amplifier  Abstract The invention relates to an electrical machine. The stator 1 is a delay line, in the form of a low-pass filter in the example, formed by inductance 11 and capacitors 12 connected between these inductances and the common conductor 131. The rotor 2 comprises dissipating elements 22 incorporated in circuits 26, separate in the example, and having a common point 25. It is put in movement by a motor. The machine operates as a high-gain amplifier having a wide band of high-frequency signals applied to the input 14 of the stator, separated from the output 15 by the decoupling zone 30. High powers are obtainable. Application to installations for testing vibration of industrial equipment and to high-power long wave radio transmission. Description The invention relates to an electrical machine capable of operating as a generator and as an amplifier. The machine comprises a fixed part, or stator, in which moves a moving part designated hereinafter by the term “rotor”, by analogy with the case of machines of the prior art in which the movement in question is a movement of rotation, although this movement may be other than a rotation and in particular a rectilinear translation in the case of the invention. The stator consists of a line having two conductors which have two input terminals and two output terminals; it’s rotor comprises resistive elements under conditions which will be described in detail later. In operation, a wave is propagated between the input terminals and the output terminals in question in this line. Electrical machines are known from U.S. Patent 3,875,484, in which the stator comprises inductances and capacitances incorporated in a transmission line, as in the machines of this invention, along which there is propagated, in operation, an electric wave, but contrary to the case of the invention, this line has only one pair of terminals to which those of the alternating current source are connected. The application of the voltage of this source between these terminals causes the rotation of the rotor of the machine which, as it is operating as a motor, does not have an output. Owing to the structure, a brief indication of which has been given above, the machine of this invention is intended, on the contrary, to operate as a generator or as an amplifier; it has an output constituted by the other pair of terminals of the stator, the rotor being driven by an exterior motor. A better understanding of the invention will be had from the ensuing description with reference to the accompanying Figures which represent:  FIG.1, diagrammatically, the stator assembly and the rotor of a machine to which the invention is applied;   Fig.2 and Fig.3, diagrammatically, an embodiment of an electrical circuit of the stator of a machine of the invention and the corresponding diagram;  Fig.4, diagrammatically, a rotor structure of the machines of the invention;  Fig.5, a diagrammatic view of a variant embodiment of the machine of the invention having a stator according to the design of Fig.2;   Fig.7 and Fig.8, diagrammatic views of two variant embodiments of the machine of the invention operating as amplifiers;   Fig.6 and Fig.9, two modifications of the machine of the invention operating as generators.  Fig.1 shows diagrammatically, a machine structure to which the invention is applied, in which the stator 1 and the rotor 2 comprise poles aligned in the direction o --- x along which the rotor movement occurs. These poles are marked as 10 and 20 and are repeated with the same horizontal spacing or pitch p in both the rotor and the stator. References 11 and 21 are the inductive windings through which the coupling occurs between a pole of the rotor and a pole of the stator when they align in the course of their movement. Vsn and Vrn are the instantaneous values of the voltages at the ends of these windings, and Isn and Irn are the currents in those coils at the moment of this alignment, n being the number assigned to the pole in each part of the machine. In order to simplify the notations, this index number ‘n’ will be omitted when mentioning the voltages and currents in question. φ designates the magnetic flux and M the coefficient of mutual inductances of this coupling. There are then obtained the following known equations:  where Ls and Lr are the values of inductances 11 and 21 and φs and φr the magnetic flux in these windings. In these equations, the quantities ω and ω' are the angular frequencies of the currents in the stator and the rotor respectively; ω = 2πf, where f is the corresponding frequency. For equal phase differences between two successive poles of the stator and rotor, the pulses ω and ω' in the relation:  where β is in accordance with the usual definition the constant of propagation of the magnetic field wave along the stator, and u is the speed at which the rotor moves in front of the stator in the direction of the reference axis o – x in the case of the machine of the embodiment of Fig.1.  if Λ and vφ respectively are the wavelength and the phase velocity in the stator. In the embodiment of the machine of this invention having a stator in the form of a low-pass filter transmission line with an input 14 and an output 15, and the inductances 11, charge-accumulating elements 12 mounted between these inductances, and a common conductor 13 as shown inFig.2 and Fig.3, there is added to the foregoing equations the following equation:  where α is equal to βp and Cs is the value of the capacitors 12 (Fig.2) included in the construction of the filter, it being observed that there is obtained with the notations of Fig.3:  There is also added:  the equation for a rotor constructed, as shown in Fig.4, by separate resistive circuits each of which comprises, in addition to the foregoing, coupling inductance 21, a resistor 22 of value Rr. By eliminating the magnitudes of flux, voltage and current between the homogeneous equations (1), (2), (3), (4), (6) and (7) and by replacing ω' with it’s expression taken from equation (5), there is obtained an equation in β whose roots have an imaginary part, whence it results that the variation with respect to time of the wave propagated along the stator in the direction o --- x of Fig.1, whose amplitude is proportional, in accordance with the conventional notation, to exp j(ωt-βx), undergoes an amplification in the course of this propagation. The equation in question is:  and assuming that α is small, that is to say, that the machine has a large number of phases in the electro-technical sense of the word, the roots of which will be calculated by their relative difference z from a reference value chosen to be equal to ω / u, which is but little different, under the conditions of operation of the machines of the invention, from the quantity β1 defined above; there is obtained:  The foregoing ratio ω/u is none other than the value of β in synchronous machines, in which ω' is null (equation 5). In the machines of this invention, ω' is non-zero: these machines operate in the asynchronous manner. The equation in z is written:  in the particular case of a coupling coefficient  It has two roots having an imaginary part. The machine is capable of amplifying a signal applied to the input of the stator. The order of magnitude of this amplification is shown below as an example. The expression of these roots is:  with:  to which the following numerical values correspond for a certain number of values of γ. The amplified wave corresponds to the root Z+.  The gain “g” in power per unit length of the stator is, according to equation (9) is:  In the given example, this gain reaches it’s maximum value for the wave corresponding to z+, for γ between 0.1 and 0.3. The imaginary part of z is then in the neighbourhood of 0.15, which gives for g, in respect of a stator whose length is 5 wavelengths (x = 5), about 40 decibels. It will be observed that the corresponding propagation constant β differs only slightly in absolute value from the constant ω/u corresponding to synchronous operation. The machine of this invention operates under conditions which differ only slightly from synchronous operating conditions. The wave passing through the stator is amplified in the manner of an electromagnetic wave which is propagated along the delay line of wave propagating tubes employed in hyper frequency described, among others, by J. R. Pierce in "Travelling Wave Tubes", Van Nostrand Co, 1950. The amplification occurs, as for these tubes, in a wide band around the central frequency. In the foregoing, the rotor has been represented, for ease of description, with a structure having poles (reference 20 in the Figures). With the scope of the invention the rotor could be in the form of the well-known squirrel-cage structure of asynchronous machines. The above calculations remain valid in giving to the notion of resistance and to the notion of inductance the signification they have in this case. The foregoing properties have been established by means of simplifying hypotheses which permit a clearer presentation. These properties apply generally to all machines whose stator and rotor would have the indicated electrical structure, even in the case of an operation which would differ slightly from these hypotheses in the neighbourhood of synchronous frequency. Moreover, the case was considered of a coupling by inductance between the rotor and the stator with a mutual coefficient M. Within the scope of the invention, this coupling could also be of an electrostatic nature between the conductors of the stator and rotor; similar equations would be obtained by substituting for the coefficient M the coefficient of electrostatic influence between the conductors in question, for the quantity Lr that, Cr, of the capacitance of each circuit of the rotor and, after interversion between Ls and Cs. In this case Vr (equation 7) represents the voltage drop at the terminals of the capacitance of the rotor. The machine of this invention is also capable of operating as a generator, as will be seen below. A few embodiments of the structure of the machine of this invention will be given here.  Fig.5 shows a first modification of this structure comprising a stator in accordance with the low-pass filter diagram of Fig.2. The rotor is a squirrel-cage, the reference numerals 322 and 33 are the bars and the end faces. In operation, it is driven by a rotor (not shown) which rotates it in the direction of the arrow about axis X which is common to the rotor and the stator of the machine. A source of alternating voltage 40 is applied to input 14 of the stator, and applied to the output 15 is a load 36, the impedance of which is equal to the characteristic impedance of the line of which the stator is part. In this arrangement of revolution about the axis X, a decoupling zone 30 separates the input and output of the stator. Further, in this zone, and in order to avoid any risk of coupling between input and output of the stator by the circuits of the rotor, there is provided any damping device considered necessary, an embodiment of which is given below. The different elements of the filter constituting the stator are damped by the resistors 16, and 18 which are connected as shown in the Figure between the windings 11 and the conductor 13 common to the terminals of the capacitors 17 and 19. Such a machine operates as an amplifier of the signal applied to the input of the stator with a gain which is of the order of 40 db in the numerical example given above. Such machines may be used as supply sources for high-power vibrators for the testing of industrial equipment of all kinds. They have the advantage over presently-known installations of this type of avoiding the steep leading edges and the high frequencies which result in their spectrum. Output powers of 100 kilowatts may be obtained with 10 watts applied at the input, with frequencies ranging up to 50 kHz. The same machine may be used as a high-power amplifier in radio broadcasting.  Fig.7 and Fig.8 give two other modifications of the arrangement of the circuits of the rotor in which the same reference numbers indicate the same components as in the preceding Figures. In Fig.8, the coupling between the rotor and stator is electrostatic. It occurs between conductors 34 and 35 when they face each other in the course of the rotation of the rotor.  In Fig.7, 110 and 112 designate the two constituent parts of the self-inductances associated with each one of the poles 10 of the stator, and 210 and 212 the parts of the self-inductances of each pole 20 of the rotor. In both Fig.7 and Fig.8, 25 is a common conductor and 26 indicates all of the elements associated with each pole of the rotor. In the modification of Fig.8, an example is given of the construction of the damping device 31 in the zone 30. A rail 38 is earthed through resistor 37 and through a contact (not shown) of the circuits of the rotor out along this rail 38 when they pass through the zone 30. The same machine is capable of operating as a generator (Fig.6 and Fig.9).  Fig.6 represents a machine whose stator is connected as a high-pass filter: each pole winding is connected at one end to the common conductor 13 and at the other end to two capacitors 12, as shown above. The filter thus constructed has a phase velocity which varies very rapidly with the frequency and in the direction opposed to that of the flux of electrical energy (inverse wave). The rotor has a velocity rather close to that of the phase velocity whereas the energy flows back to the load 36 in the opposite direction. The upstream side (for the energy) of the filter terminates on the characteristic impedance 42 of the filter. A generator is obtained in this way having a frequency which is determined within a wide band by the speed of rotation of the rotor. In the example shown in the Figure, the rotor has a squirrel-cage structure.  The machine of Fig.9 differs from that of Fig.6 by the addition of supplementary capacitors 120 arranged in parallel with the inductances 11. The circuit thus obtained is an inverse wave band-pass filter. The width of its band-pass is determined by the respective values of the capacitors 12 and 120. The phase velocity remains rapidly variable as a function of the frequency. The machine operates as a generator, the frequency of which, depends only very slightly on the velocity of rotation of the rotor. The RotoVerter. Not all pulsed-drive systems use permanent magnets as part of their drive mechanism. For example, the RotoVerter systems uses standard three-phase electric motors instead of magnets. In addition, some of the electrical driving power can be recovered for re-use. This system has been reproduced by several independent researchers and it produces a substantial power gain when driving devices which need an electrical motor to operate. The outline details are as follows:  The output device is an alternator which is driven by a three-phase mains-powered, 3 HP to 7.5 HP motor (both of these devices can be standard ‘asynchronous squirrel-cage’ motors). The drive motor is operated in a highly non-standard manner. It is a 240V motor with six windings as shown below. These windings are connected in series to make an arrangement which should require 480 volts to drive it, but instead, it is fed with 120 volts of single-phase AC. The input voltage for the motor, should always be a quarter of its rated operational voltage. A virtual third phase is created by using a capacitor which creates a 90-degree phase-shift between the applied voltage and the current.  The objective is to tune the motor windings to give resonant operation. A start-up capacitor is connected into the circuit using the press-button switch shown, to get the motor up to speed, at which point the switch is released, allowing the motor to run with a much smaller capacitor in place. Although the running capacitor is shown as a fixed value, in practice, that capacitor needs to be adjusted while the motor is running, to give resonant operation. For this, a bank of capacitors is usually constructed, each capacitor having its own ON/OFF switch, so that different combinations of switch closures give a wide range of different overall values of capacitance. With the six capacitors shown above, any value from 0.5 microfarad to 31.5 microfarad can be rapidly switched to find the correct resonant value. These values allow combined values of 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, .....by selecting the appropriate switches to be ON or OFF. Should you need a value greater than this, then wire a 32 microfarad capacitor in place and connect the substitution box across it to test higher values step by step to find the optimum value of capacitor to use. The capacitors need to be powerful, oil-filled units with a high voltage rating - in other words, large, heavy and expensive. The power being handled in one of these systems is large and setting one up is not without a certain degree of physical danger. These systems have been set to be self-powered but this is not recommended, presumably because of the possibility of runaway with the output power building up rapidly and boosting the input power until the motor burns out. The Yahoo EVGRAY Group at http://groups.yahoo.com/group/EVGRAY has a large number of members, many of whom are very willing to offer advice and assistance. A unique jargon has built up on this forum, where the motor is not called a motor but is referred to as a “Prime Mover” or “PM” for short, which can cause confusion as “PM” usually stands for “Permanent Magnet”. RotoVerter is abbreviated to “RV” while “DCPMRV” stands for “Direct Current Permanent Magnet RotoVerter” and “trafo” is a non-standard abbreviation for “transformer”. Some of the postings in this Group may be difficult to understand due to their highly technical nature and the extensive use of abbreviations, but help is always available there. To move to some more practical construction details for this system. The motor (and alternator) considered to be the best for this application is the “Baldor EM3770T” 7.5 horsepower unit. The specification number is 07H002X790, and it is a 230/460 volts 60Hz 3-phase, 19/9.5 amp, 1770 rpm, power factor 81, device. The Baldor web site is here and the following details should be considered carefully before trying any adaption of an expensive motor. The following constructional photographs are presented here by kind permission of Ashweth Palise of the EVGRAY Group. The end plate of the drive motor needs to be removed and the rotor lifted out. Considerable care is needed when doing this as the rotor is heavy and it must not be dragged across the stator windings as doing that would damage them.  The second end-plate is then removed and placed on the opposite end of the stator housing.  The fan is removed as it is not needed and just causes unnecessary drag, and the rotor is inserted the opposite way round to the way it was removed. That is, the housing is now the other way round relative to the rotor, since the rotor has been turned through 180 degrees before being replaced. The same part of the shaft of the rotor passes through the same end plate as before as the end plates have also been swapped over. The end plates are bolted in position and the rotor shaft spun to confirm that it still rotates as freely as before. To reduce friction to an absolute minimum, the motor bearings need to be cleaned to an exceptional level. There are various ways of doing this. One of the best is to use a carburettor cleaner spray from your local car accessories shop. Spray inside the bearings to wash out all of the packed grease. The spray evaporates if left for a few minutes. Repeat this until the shaft spins perfectly, then put one (and only one) drop of light oil on each bearing and do not use WD40 as it leaves a residue film. The result should be a shaft which spins absolutely perfectly. The next step is to connect the windings of the two units. The motor (the “Prime Mover”) is wired for 480 volt operation. This is done by connecting winding terminals 4 to 7, 5 to 8 and 6 to 9. The diagram shows 120 volts AC as being the power supply. This is because the RotoVerter design makes the motor operate at a much lower input than the motor designers intended. If this motor were operated in the standard way, a 480 volt 3-phase supply would be connected to terminals 1, 2 and 3 and there would be no capacitors in the circuit.  It is suggested that the jumpering of the motor windings is more neatly done by removing the junction box cover and drilling through it to carry the connections outside to external connectors, jumpered neatly to show clearly how the connections have been made for each unit, and to allow easy alterations should it be decided to change the jumpering for any reason.